Lifting the lid on boat build impacts for a more sustainable industry

Only by prioritizing sustainability along with performance, can the marine industry take urgent action to fight climate change. What these actions could look like are explored in the Design & Build report our team has published following the construction of the new race boat Mālama.

Following the official launch in September 2021 of Mālama, the latest high-performance IMOCA race boat, 11th Hour Racing Team has published a comprehensive design and build report in both English and French.

Sharing detailed insights into the boat’s construction, material components, supply chain, and environmental impact, the report aims to drive positive action within the marine industry and provide a roadmap for aligning with international frameworks for positive climate action, including the UNFCCC (United Nations Framework on Climate Change) and the Paris Agreement.

Damian Foxall, Sustainability Manager at 11th Hour Racing Team, explains how the Team has used the boat build as an example of how sustainable innovation could be implemented across the wider industry:

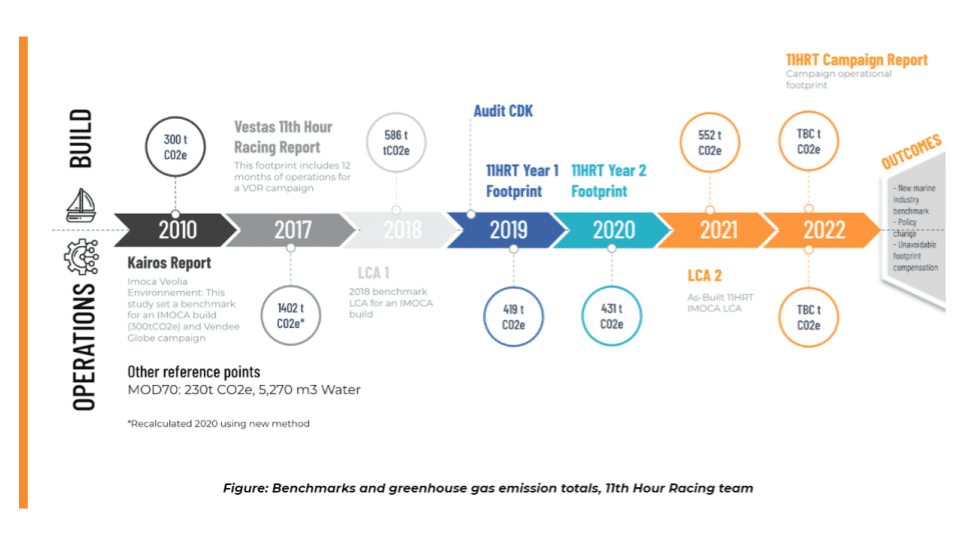

“Over the past ten years, there has been amazing progress in on-water performance in our class, but this has come at a high price. Since 2010, the footprint of an IMOCA has increased by nearly two-thirds from 340 to 550 tons in greenhouse gas emissions. This is an overall trend we see in pretty much any industry, driven by performance we have accelerated too fast in the wrong direction, and are only just waking up to reality.”

Referencing the Paris Agreement as a global target for energy savings, Foxall continues:

“The need to reduce our emissions in the marine industry is urgent – 50% by 2030 and that’s just eight years away. We are far away from that right now.”

In order to get back on track and reduce emissions, it is crucial to understand where exactly the emissions are coming from. This is often easier said than done, as Amy Munro, Sustainability Officer at 11th Hour Racing Team, explained:

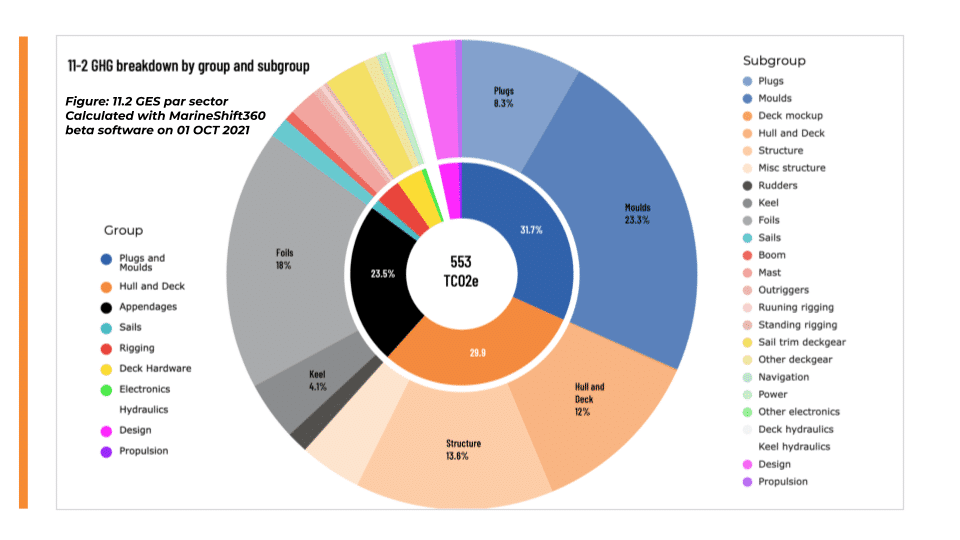

“Building a race boat is a complex process involving a huge number of stakeholders and components. You need to break it down in detail to fully understand what are the major impacts. This is why we have meticulously measured the impact of every step in the design and build process of our new boat and conducted a life cycle analysis (LCA) that helps to uncover underlying issues. This way we were able to address the issues during the build and find opportunities and solutions to make the shift.”

SUSTAINABLE DESIGN & BUILD REPORT RESOURCES

The full report available in French and English, along with additional resources can be downloaded below:

Key impacts from the 11th Hour Racing Team LCA include:

- Greenhouse Gas Emissions (C02e):

- The total emission of greenhouse gases was 553 tCO2e (metric tons of carbon dioxide equivalent). This amount is the equivalent of 1.4 million miles (2.2 million kilometers) driven by an average passenger vehicle – 55 times around the equator – or the average footprint of manufacturing 100 Renault cars.

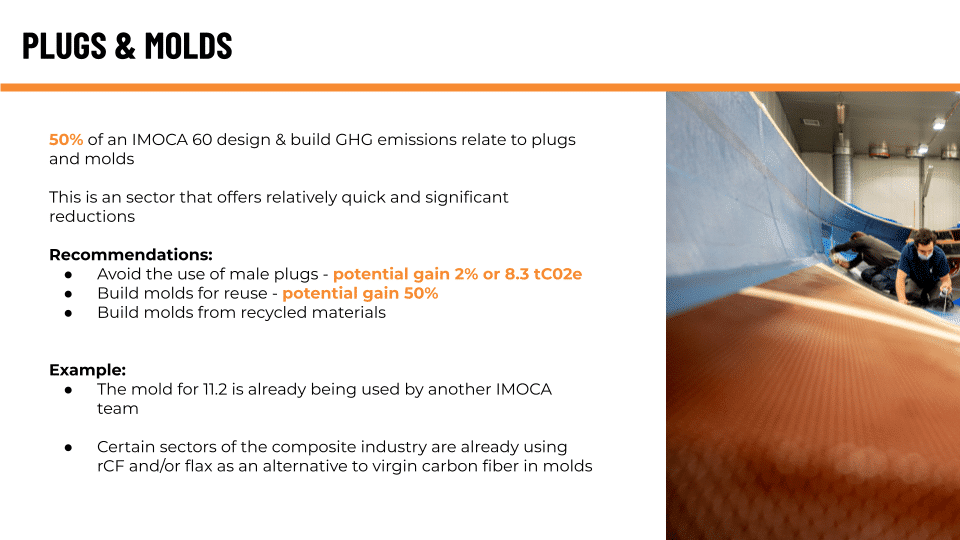

- More than 80% of greenhouse gas emissions in the boat build are associated with the use of composite materials, most notable is virgin carbon fiber. Finding alternative solutions or reducing the use of virgin carbon fiber, will significantly reduce the greenhouse gas emissions of a new boat build.

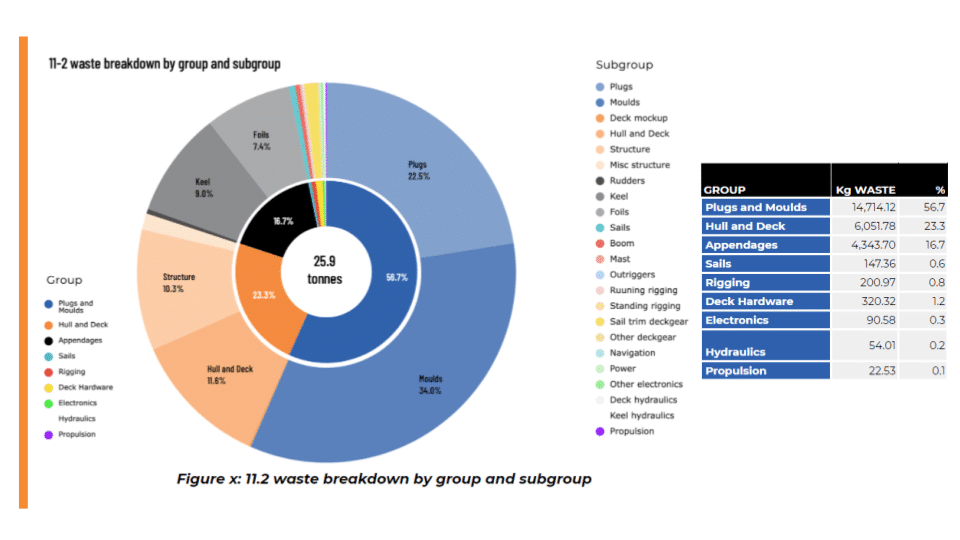

- Resource consumption: 34.5 tons of material were used to build an 8.6-ton boat, which is primarily made up of high-tech materials such as carbon fiber.

- Energy consumption (millijoule or mJ) The energy consumed by the production of materials and build process of the boat was 15.9 million mJ, equivalent to 370 North American homes’ energy use for one year.

- Water consumption: The total quantity of water used in the production of the goods and services associated with the design and build of the IMOCA was 7,500 m3 (7.5 million liters or 2 million US gallons), which is the equivalent of three Olympic swimming pools.

Recommendation Highlights

Following the saying, ‘You can only manage what you can measure’, 11th Hour Racing Team used these findings to optimize Mālama’s build process wherever possible and established recommendations for future IMOCA boat builds.

Energy sourcing and consumption:

- Make renewable energy a key point of discussion across your supply chain, and sourcing contracts.

- Ensure manufacturing energy needs are sourced from 100% renewable energy tariffs, for instance, the Team’s boat builder CDK Technologies was on 100% renewable energy resulting in a 15% reduction compared to EU average.

- Don’t forget the digital footprint of your project. The Team’s digital footprint was 15 tons C02e, similar to the global greenhouse gas emissions figure of 3.5% and which is predicted to reach up to 14% by 2040!

Materials and components: Implement efforts to replace materials such as carbon fiber and epoxy resin, with alternative materials such as recycled carbon, flax or bio-resin. Here are some (non-exhaustive) examples from the report:

- Bio-resins: The team used bio-based resins (Sicomin Greenpoxy and Gurit’s Ampro Bio) in components like the splashes, engine box, deck fairing, and hatches. Bio-based resins have approximately a 50% lower carbon footprint, use half the amount of scarce resources, and consume 50% less energy and water than an average non-bio-based resin.

- Recycled PET core: The Team used recycled PET core for some components, such as cradles, engine boxes and deck fairings, which has a 56% lower global warming potential than virgin PET core.

- Recycled carbon (rCF): producing only 5-20% of the greenhouse gas emissions of virgin carbon fiber, recycled carbon often provides a valid alternative, in particular for nonstructural parts and molds. The production of rCF highly depends on adequately recycled carbon cut-offs, and the team has processed nearly five metric tons of carbon composite during the build of Mālama.

- Flax: This versatile renewable material has a number of properties that make it a valid low impact alternative material. 11th Hour Racing Team has worked with Greenboats, a German start-up, to supply three hatches made using bio-resin, flax fiber, recycled PET, and balsa cores. Overall, 80m2 of flax was used on the boat, with the fibers being CO2 neutral over their life cycle and bio-decomposable.

Supply chain:

- Shorten supply chains by working with providers that are close in proximity. By basing themselves in the heart of the offshore sailing world, the Team was able to invest over 80% of 11th Hour Racing Team’s supplier budget locally in Brittany, France.

- Choose suppliers that have sustainability protocols in place that are in line with established rules and regulations within your sector. If suppliers don’t have these protocols, offer to work together to help put them in place!

Waste management and circularity: A ‘low-hanging fruit’ when it comes to footprint reduction is putting an efficient waste management system in place – recycle or reuse where possible. Throughout the build, the team achieved 21 tons of waste diverted from landfill (81%).

- Identify areas to reduce waste, such as working with suppliers to avoid unnecessary packaging. The team worked with boat builders CDK Technologies and Gurit, a high-volume supplier, on a financially incentive cardboard packaging take-back program.

- Identify areas of high emission impact and implement circularity principles. In Mālama’s case, the hull and deck mold represented 50% of its CO2 footprint. By reusing it for other boats, this will significantly lower the impact of future builds.

Collaboration: Partnerships and collaboration are fundamental drivers to a shift from ‘business as usual’. 11th Hour Racing Team encourages the boating industry to actively share learnings and set bold policy in line with the frameworks established by organizations like the UNFCCC. To build Mālama, the Team has worked with a global network of experts including the likes of CDK Technologies, MerConcept, Kairos Biocomposites, Greenboats, Navico, Guillaume Verdier Design, the IMOCA Class and more.

After 18 months in the build shed, the roll-out of Mālama in September 2021 was a seminal moment for the entire team. CEO Mark Towill explains:

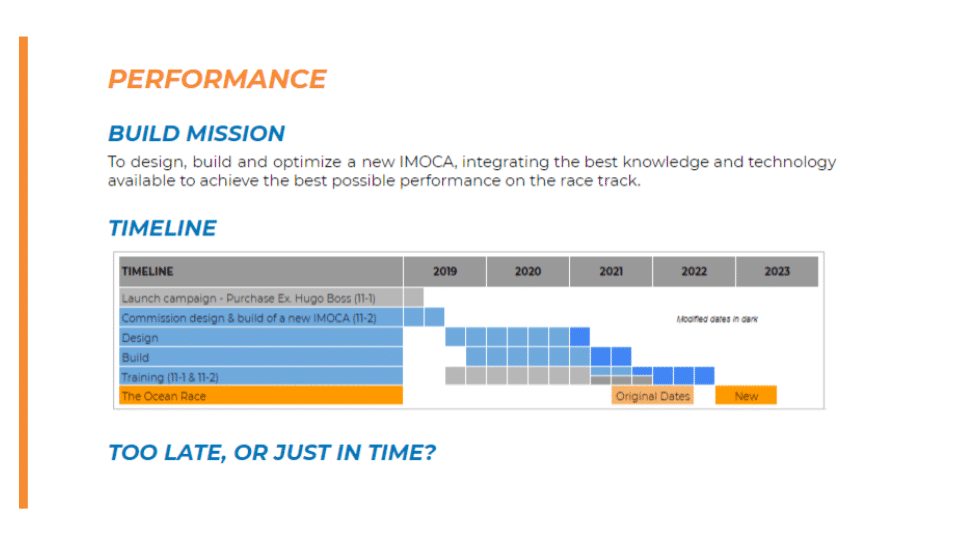

“As intended, Mālama has become a pilot project for sustainable innovations, and there are many areas of the build where we would have liked to push even further in this space. However, one key learning of this process was the timeline constraints associated with implementing these innovations, such as the use of alternative materials. There are significant lead times associated with the research, development and testing of alternative materials in order to have proven solutions that are to the same structural and safety standards of what’s currently being used in new boat builds. Our aim is that this report provides insight into the barriers and opportunities for innovation to be more broadly incorporated into future builds.”

The outcome of the overall design and build process and the recommendations in the report, outline a vision for Net-zero as part of defining our sport and industry within a sustainable future.

To share their findings, the Team will participate in a number of workshops hosted by the IMOCA Class in 2022, sharing hands-on experiences with peers and experts from other teams and across the industry. Follow the Team’s social channels for more information.